Overview

From 3.5b2, it is now possible to use one or two toolboards with an STM32F4 based board using the CAN-FD protocol. To do so, you must purchase a separate SPI to CAN-FD module. TeamGloomy have worked with Flymaker/Mellow to produce 2 designs of module to suit the board you are using.

For the SKR Pro v1.2 we recommend the driver module, which can be purchased from Aliexpress.

Connecting the driver module (DFD)

You need either a spare driver slot or you replace an extruder driver with a toolboard. The driver slot should ideally be the last one on the board and have a working voltage of 24v.

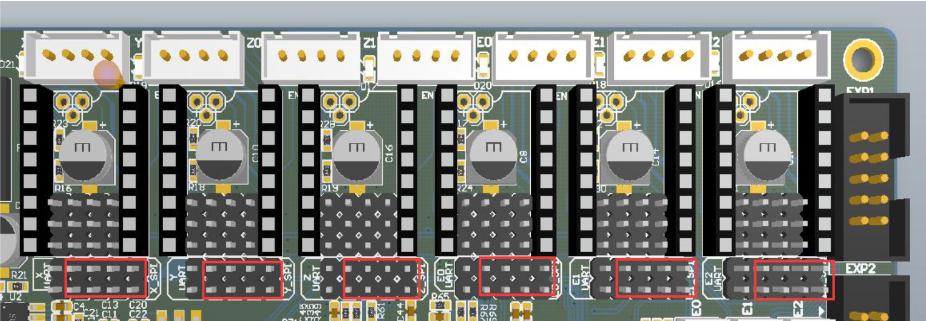

The driver slot you are going to use should be put in SPI mode. This is done using jumpers as shown below.

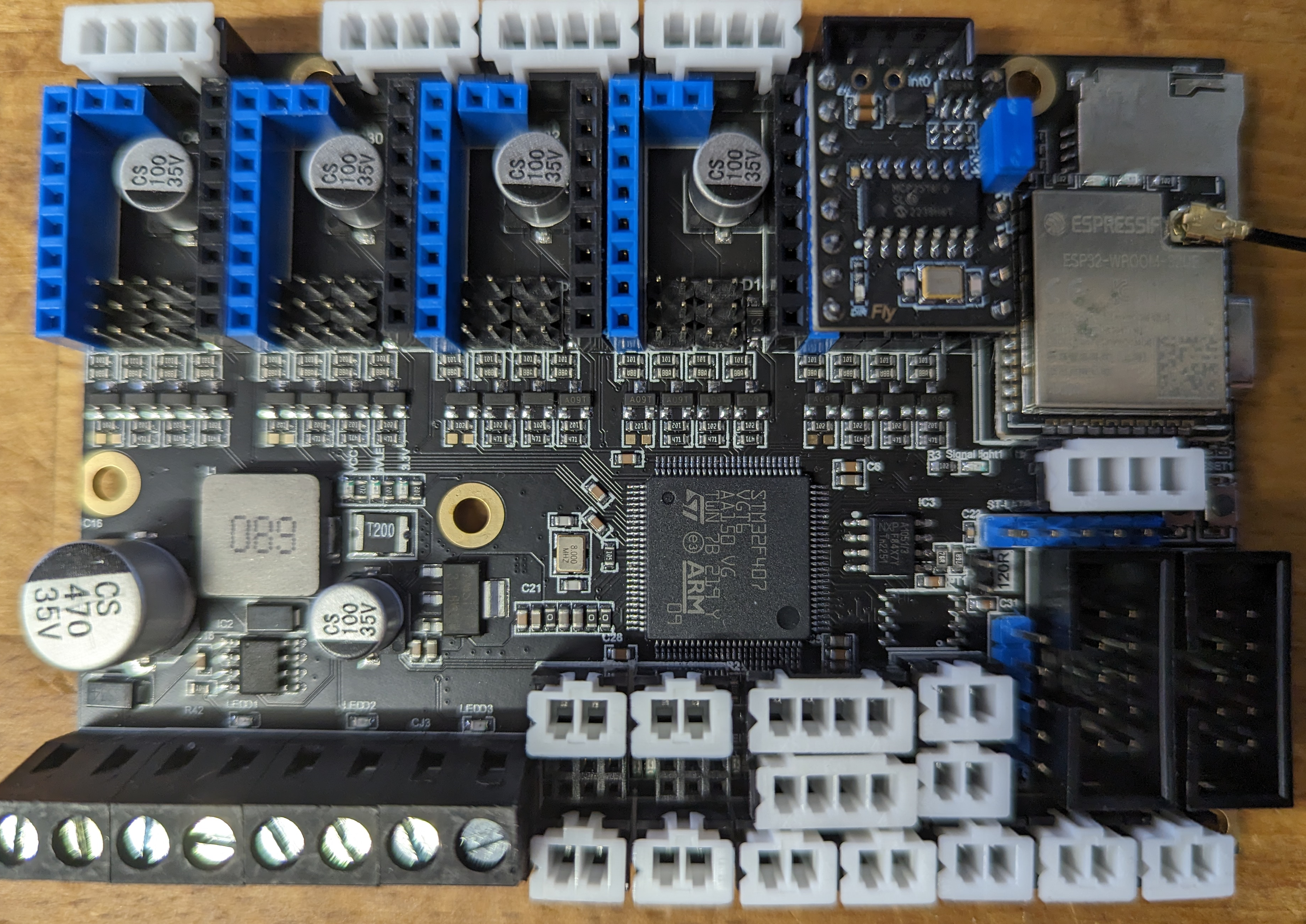

Install the driver module. Ensure the module is installed so the hole thats in the same position as the diag pin is closest to the driver socket.

Also make sure you install the jumper as shown below.

Wiring for the driver module

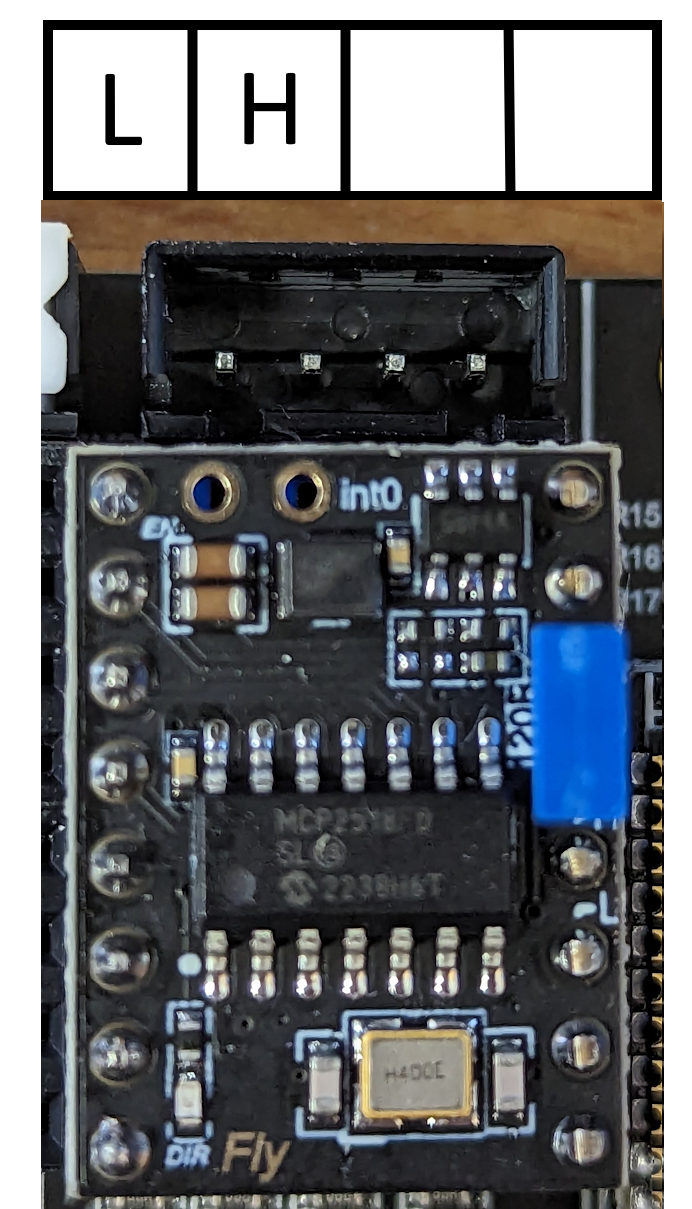

CAN-FD only requires 2 wires to be connected between each board, CAN-H and CAN-L.

We recommend using stranded twisted wire pairs, such as those found in ethernet patch cables.

Using the image below, the H connection is the CAN-H connection and should be connected to CAN-H on the toolboard. L is the CAN-L connection and should be connected to CAN-L.

Board.txt changes

The following two lines should be added to board.txt and assume the last driver slot is used. If another driver slot is used the appropriate CS pin must be chosen.

//CAN-FD Interface

can.csPin = PG_12

can.spiChannel = 2

Don’t forget to reduce the number of smart drivers if you are replacing a driver with the drive SPI to CAN-FD module.

If you are running the DFD module at the same time as 5160 drivers, it is recommended to slow down the SPI connection. To do so, add the following line to your board.txt.

can.spiFrequencyHz = 10000000

Config.g Changes

If successful, the toolboard should show in the object model.

See this page for more information about CAN addresses etc.