Overview

The MKS Sbase v1.3 is an LPC1768 based board.

Firmware File

Choose the correct corresponding firmware (firmware-lpc-wifi-XXX.bin) from here. Remember to rename it to firmware.bin. Put it in the root of a FAT32 formatted SD card.

ESP8266 WiFi

I’ve used a nodemcu ESP8266 with USB programming as it already 5v tolerant and it allows for updating via USB.

Background

The main problem is that MOSI0 is not available at a pin header other than the LCD headers and there it is only available via a level shifter.

Unfortunately that level shifter is one way and so MOSI0 can only be used as an output, but in the case of the ESP8266 WiFi module on the LPC, it is an SPI slave device, not a master and so this pin needs to be used as an input, which means it is not going to work.

All of the other MOSI0 lines can be found on J7 but unfortunately not 0.18.

MOSI0 can be routed either to pin 0.18 or to pin 1.24. 1.24 is the X-min endstop pin so is externally accessible. However it has a small filter (couple of resistors and a capacitor) hooked up to it and these prevent the high speed SPI signal from being read by the MCU.

Modification of the MKS Sbase v1.3

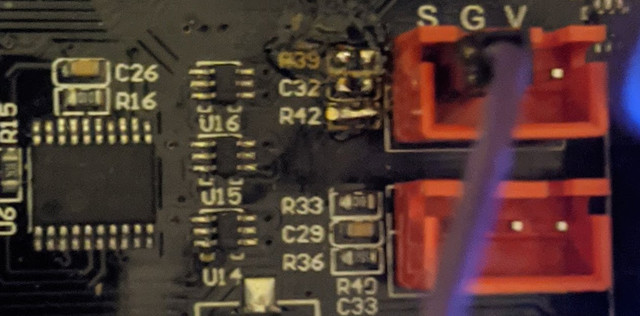

As 1.24 (the Xmin pin) is most easily accessible, we are going to go that route. Three components need to be removed from the board using a soldering iron. They are R39, R42 and C32 and can be found next to the Xmin endstop. Once removed, R42 (the bottom one) should be bridged. A small piece of wire can be used (in the image below, it was a small piece of resistor leg).

BOM

- 1 x nodemcu ESP8266 or Wemos D1 mini

- 3 x 47R resistor

- 1 x 470R resistor

- 3 x 2200R resistor

- jumpers or other ways of connecting to the MKS Sbase

Preparing the ESP8266

Follow the instructions here.

Connecting the ESP8266

The pinout for the MKS Sbase v1.3 can be found here and the schematic for the Duet 2 WiFi for reference can be found here.

The table below shows the pins required on the ESP8266 and what they are connected to on the SKR. Please ensure that your cables are no longer than 30cm although they should ideally be as short as possible.

| ESP8266 Pin | MKS Sbase Pin | Resistor Value |

|---|---|---|

| RST | 1.31 on EXP1 | 470R |

| CS/GPIO15 | 0.16 on J7 | 2200R |

| MOSI/GPIO13 | 1.24 on xstop | 47R |

| MISO/GPIO12 | 0.17 on J7 | 47R |

| SCLK/GPIO14 | 0.15 on J7 | 47R |

| ESP_DATA_Ready/GPIO0 | 2.11 on J8 | 2200R |

| LPC_DATA_Ready/GPIO4 | 1.30 on EXP1 | None |

| VIN(5v) | 5v on EXP1 | None |

| GND | GND on EXP1 | 2200R to RST |

Prepare the SD Card

Follow the instructions on Getting Started with RRF3

Board.txt file

You will also need a board.txt file in the sys folder. Below are the contents that should be used.

//Config for MKS Sbase v1.3

board = mkssbase_1.3

//WiFi pins

8266wifi.espDataReadyPin = 2.11

8266wifi.TfrReadyPin = 1.30

8266wifi.espResetPin = 1.31

SSP0.pins = {0.15, 0.17, 1.24, 0.16}

heat.tempSensePins = { 0.23, 0.24, 0.25 }

Updating the ESP8266 by RRF

If you have an ESP8266 WiFi adapter that supports updating via RRF, you need to add the following information to the board.txt file.

8266wifi.serialRxTxPins = { 0.3, 0.2 }

serial.aux.rxTxPins = { nopin, nopin }

Final Setup

Once connected, power up the board using 12-24v and connect to the USB port on the board. Using a program such as putty. Follow the instructions here to set it up for RRF. Then type in the following

text

M997 S1

Wait for the uploading of the WiFi firmware to finish. Then send the following

text

M552 S-1

Continue with the instructions below.M552 S0

M587 S"your SSID" P"your password"

M552 S1

If you wanted to use “PassWord”, you would write P”P’a’s’sW’o’r’d” with the ‘ indicating the following letter should be lower case. Explanation here.

The blue light on the WiFi chip shoould then flash blue and will go solid when a connection has been established. The ip address will be shown on the serial connection. It is also possible to type just M552 to get the current ip address reported back.

The final thing to do is add the line “M552 S1” to your config file. This can be done through the web interface. This just ensures that the WiFi connection is started at start up. There is no need to add the M587 command as this is written permanently to the flash of the ESP8266 chip.

Once up and running

You will need to PID tune your tools and your bed. Please be aware that bed tuning may take up to an hour and tool tuning normally takes around 15 minutes. If it takes longer, that is also fine as up to 30 cycles may be ran.

To tune the bed, run the following command, changing the temperature (the S value) if a different tuning temperature is required.

M303 H0 S60

To tune each tool, run the following command, changing the temperature (the S value) if a different tuning temperature is required. This proceedure will activate the part cooling fans during the final phase of the tuning process so their effect is taken into account. If your printer has more than one tool, make sure each one of them is tuned.

M303 T0 S220

Once the tuning is complete, either copy the M307 command into the heater definitions or send M500, ensuring you have M501 at the end of your config.g.

If the tuning fails at the end, carry on saving the values as in most cases the outputted values still work correctly.

If the values still result in a heater fault, please refer to this wiki page for information about how to adjust the values manually.